- Home

- >

- Products

- >

- Special Injection Moulding Machine

- >

- Professional High Speed Machine

- >

- SHE298H Professional High Speed Machine

SHE298H Professional High Speed Machine

Series :Professional High Speed Injection Molding Machine

Brand :SANSHUN

Model :SHE298H

Applications :Thin wall boxes, Food packaging box, plastic spoon, fork and knife

SANSHUN Machinery is one of the top 10 Chinese injection molding machinery manufacturer. We are manufacturing different types of injection molding machines, injection blow molding machine, and Auxiliary equipment. Our machines had been exported to more than 60 countries.

Characteristics

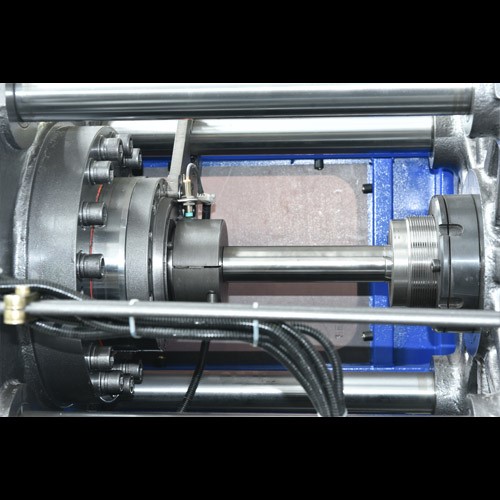

Maximum speed, dynamics and performance: The Sanshun high Speed Injection Molding Machine is trimmed for durable high-performance from top to tail. All system components withstand the most exacting demands and are thus ideally suited for intensive use in the packaging industry. Designed for permanent high-speed and maximum output With the short period between cycles, a greater quantity of molds can be produced in a limited amount of time, thus increasing possible revenue and profit margins , it does help improve efficiencies within the factory and this, in turn, creates savings for the customer. High Speed Injection System consists of an injection and a plasticizing unit. On the injection axis, a High Torque Direct Drive Servomotor works together with a planetary gearbox and a nonlinear actuator to provide the translational movement of the injection axis. Another High Torque Direct Drive Servomotor rotates the plasticizing screw.

Advantages

short cycle times, perfect cleanliness, improved efficiency,Tailored for Thin Wall Applications , Higher Productivity, Greater Efficiency, Low Maintenance, Versatility, Reduced waste, Low labor costs

Technical Parameters

| MODEL | UNIT | SHE298-H | |

| INJECTION UNIT | A | B | |

| Screw diameter | mm | 50 | 52 |

| Shot size(theoretical) | Cm³ | 392 | 425 |

| Shot weight | g | 352 | 382 |

| Injection pressure | Mpa | 255 | 236 |

| Injection speed | g/s | 360 | 390 |

| Screw L/D ratio | L/D | 26 | 25 |

| Screw speed | r.p.m | 0-300 | |

| Nozzle Diameter | Srmm | 15 | |

| CLAMPING UNIT | |||

| Clamp tonnage | KN | 2980 | |

| Toggle stroke | mm | 560 | |

| Mould Thickness | mm | 200-600 | |

| Space between tie-bars | mm | 620x583 | |

| Ejector stroke | mm | 140 | |

| Ejector tonnage | mm | 80 | |

| OTHERS | |||

| Heat power | KW | 28.7 | |

| Max. pump pressure | MPa | 16 | |

| Pump motor power | KW | 39.8+39.8 | |

| Machine dimension | m | 7.4X2.0X1.95 | |

| Machine weight | t | 15.8 | |

| Oil Tank Capacity | l | 700 | |

Advantages & Features

|