- Home

- >

- Products

- >

- Special Injection Moulding Machine

- >

- Nylon Cable Injection Molding Machine

- >

- SHE360HD Nylon Cable Injection Molding Machine

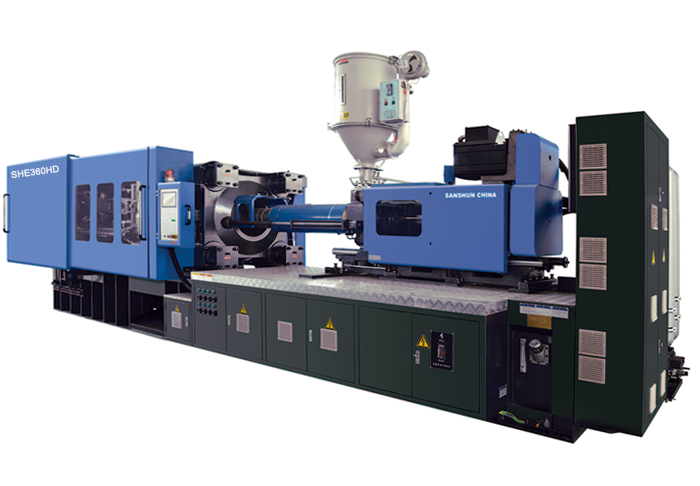

SHE360HD Nylon Cable Injection Molding Machine

Series :Nylon Cable Tie Injection Molding Machine

Brand :SANSHUN

Model :SHE360HD

Applications :Nylon Cable Tie Manufacturing

SANSHUN Machinery is one of the top 10 Chinese injection molding machinery manufacturer. We are manufacturing different types of injection molding machines, injection blow molding machine, and Auxiliary equipment. Our machines had been exported to more than 60 countries.

Characteristics

Nylon cable tie injection molding machine is one of our flagship model machine. Sanshun made specialized machine because the machine is set up specifically to run nylon ties, so the tooling, the hot runners, the barrel and screw will be set up to run Nylon 6, the drier will keep the nylon to just the right moisture content, the take off equipment will be what's needed, the statistical process controller will be tuned for nylon cable ties etc.

Advantages

Short cycle time, higher productivity, low noise, quick response, high-efficiency, high-speed automation, stable weight consistency, low power consumption, full automation of the process

Technical Parameters

| MODEL | UNIT | SHE360-HD | |

| INJECTION UNIT | A | B | |

| Screw diameter | mm | 65 | 70 |

| Shot size(theoretical) | Cm³ | 990 | 1150 |

| Shot weight | g | 900 | 1046 |

| Injection pressure | Mpa | 163 | 141 |

| Injection rate | g/s | 147 | 147 |

| Screw L/D ratio | L/D | 19.4 | 22 |

| Screw speed | r.p.m | 0-200 | |

| Nozzle Diameter | Srmm | 20 | |

| CLAMPING UNIT | |||

| Clamp tonnage | KN | 3600 | |

| Toggle stroke | mm | 520 | |

| Mould Thickness | mm | 210-550 | |

| Space between tie-bars | mm | 670X670 | |

| Ejector stroke | mm | 140 | |

| Ejector tonnage | KN | 85 | |

| Ejector number | Piece | 13 | |

| Hole Diameter | mm | 110 | |

| OTHERS | |||

| Heat power | KW | 16.5 | |

| Max. pump pressure | MPa | 16 | |

| Pump motor power | KW | 37+37 | |

| Machine dimension | m | 7.2X1.9X2.1 | |

| Machine weight | t | 14.5 | |

| Oil Tank Caacity | L | 500 | |

Advantages & Features

|