- Home

- >

- Products

- >

- Injection Molding Machine

- >

- Variable Energy Saving Injection Moulding Machine

- >

- SHE338V Variable Energy Saving Injection Moulding Machine

SHE338V Variable Energy Saving Injection Moulding Machine

Series : Variable Energy Saving Injection Moulding Machine

Brand :SANSHUN

Model :SHE338V

Applications :For making plastic products

SANSHUN Machinery is one of the top 10 Chinese injection molding machinery manufacturer. We are manufacturing different types of injection molding machines, injection blow molding machine, and Auxiliary equipment. Our machines had been exported to more than 60 countries.

Characteristics

Sanshun Variable Pump equipped Plastic Injection Molding Machines consumes 30–35% less energy compared to a fixed pump. It is mostly used for high speed (packaging components) IMM as the cooling time for the components is negligible. So the motor runs continuously performing operations. Variable pump injection machine, at the same speed, can change the displacement of the hydraulic pump, and the motor load will also change with displacement, so as to save electricity. The main difference between the variable quantity pump and standard pump is output power, output power of the variable pump is changed with the load change, and the output power of the pump is relatively constant, in a small flow of actions, the output power of the variable pump is very low, but the quantitative pump output power constant

Advantages

variable-displacement pump, Economical, Energy saving, environmental, constant-speed motor, quick response, Improve Production efficiency

Technical Parameters

| MODEL | SHE338V | ||

| INJECTION UNIT | UNIT | A | B |

| Screw diameter | mm | 58 | 60 |

| Shot size(theoretical) | Cm³ | 858 | 918 |

| Shot weight | g | 772 | 826 |

| Injection pressure | Mpa | 180 | 168 |

| Injection rate | g/s | 254 | 272 |

| Screw L/D ratio | L/D | 22.2 | 21.5 |

| Screw speed | r.p.m | 0-180 | |

| Nozzle Diameter | Srmm | 12 | |

| CLAMPING UNIT | |||

| Clamp tonnage | KN | 3380 | |

| Toggle stroke | mm | 580 | |

| Mould Thickness | mm | 270-650 | |

| Space between tie-bars | mm | 640X640 | |

| Ejector stroke | mm | 160 | |

| Ejector tonnage | KN | 80 | |

| Ejector number | Piece | 13 | |

| Hole Diameter | mm | 160 | |

| OTHERS | |||

| Heat power | KW | 19.5 | |

| Max. pump pressure | MPa | 16 | |

| Pump motor power (servo) | KW | 40 | |

| Pump motor power (fixed pump) | KW | 30 | |

| Valve Size | mm | 25 | |

| Machine dimension | m | 6.7X2.0X2.05 | |

| Machine weight | t | 10.8 | |

| Oil tank capacity | L | 400 | |

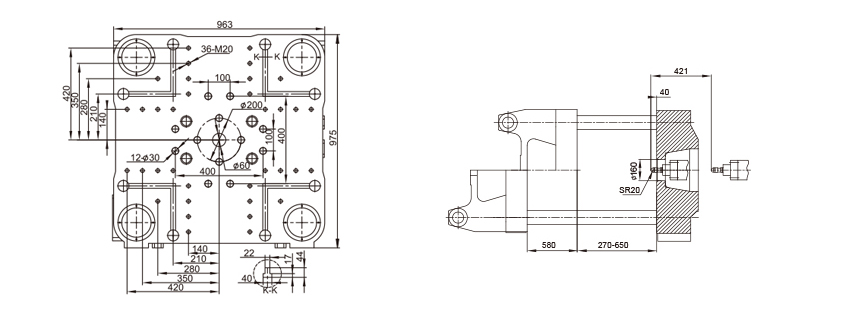

Platen Dimensions

Advantages & Features

|