- Home

- >

- Products

- >

- Injection Molding Machine

- >

- Fixed Pump Injection Moulding Machine

- >

- SHE688 Fixed Pump Injection Moulding Machine

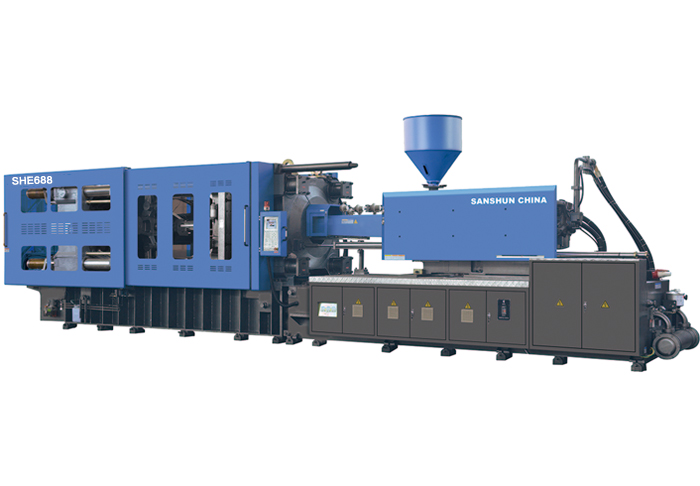

SHE688 Fixed Pump Injection Moulding Machine

Series :Fixed Pump Injection Moulding Machine

Brand :SANSHUN

Model :SHE688

Applications :For making plastic products

SANSHUN Machinery is one of the top 10 Chinese injection molding machinery manufacturer. We are manufacturing different types of injection molding machines, injection blow molding machine, and Auxiliary equipment. Our machines had been exported to more than 60 countries.

Characteristics

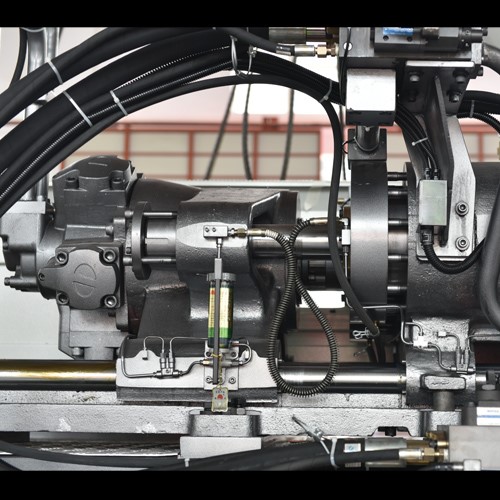

Sanshun Fix Pump equipped Plastic Injection Molding Machines A fixed-displacement pump has a set flow rate — every stroke of the motor moves the same amount of fluid. The simplest type of fixed-displacement pump is the gear pump, in which the hydraulic fluid is pushed by rotating gears. In some models, the gears are sequential; in the quieter and more efficient version, the gears are interlocking. Another common variation is the screw pump, which uses the classic Archimedes screw, which looks much like a drill bit, to move the fluid. They have the advantage of providing a high rate of flow at relatively low pressures. Fixed pump system provides stable output, quick response, powerful strength. The hydraulic oil flow design applied modular block technology for rapid oil transfer and dynamic system response

Advantages

Simple, Relatively inexpensive, environmental, set flow rate, Easier to maintain

Technical Parameters

| MODEL | SHE688 | ||

| INJECTION UNIT | UNIT | A | B |

| Screw diameter | mm | 98 | 100 |

| Shot size(theoretical) | Cm³ | 3780 | 3920 |

| Shot weight | g | 3400 | 3530 |

| Injection pressure | Mpa | 150 | 144 |

| Injection rate | g/s | 650 | 676 |

| Screw L/D ratio | L/D | 20.5 | 20 |

| Screw speed | r.p.m | 0-110 | |

| Nozzle Diameter | Srmm | 18 | |

| CLAMPING UNIT | |||

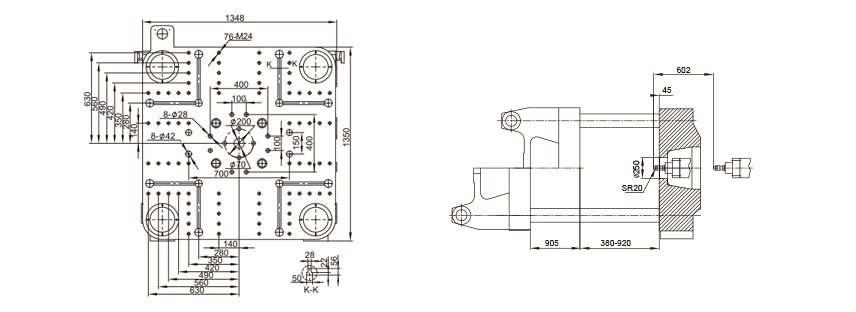

| Clamp tonnage | KN | 6880 | |

| Toggle stroke | mm | 905 | |

| Mould Thickness | mm | 380-920 | |

| Space between tie-bars | mm | 915X914 | |

| Ejector stroke | mm | 260 | |

| Ejector tonnage | KN | 180 | |

| Ejector number | Piece | 13 | |

| Hole Diameter | mm | 250 | |

| OTHERS | |||

| Heat power | KW | 45 | |

| Max. pump pressure | MPa | 16 | |

| Pump motor power(servo) | KW | 41+41 | |

| Pump motor power (fixed pump) | KW | 30+30 | |

| Machine dimension | m | 10X2.3X2.35 | |

| Machine weight | t | 32 | |

| Oil tank capacity | L | 1100 | |

Platen Dimensions

Advantages & Features

|