- Home

- >

- Products

- >

- Special Injection Moulding Machine

- >

- Auto-car Part Injection Molding Machine

- >

- SHE230 Auto-car Part injection molding machine

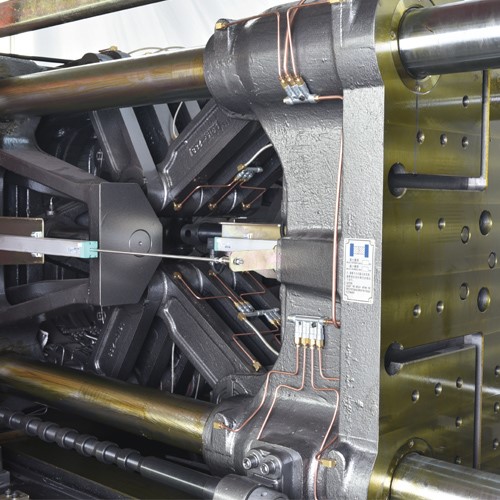

SHE230 Auto-car Part injection molding machine

Series :Automotive industry

Brand :SANSHUN

Model :SHE230

Applications : For manufacturing Car and other Vehicle parts

SANSHUN Machinery is one of the top 10 Chinese injection molding machinery manufacturer. We are manufacturing different types of injection molding machines, injection blow molding machine, and Auxiliary equipment. Our machines had been exported to more than 60 countries.

Characteristics

Sanshun Injection Molding Machines Special series for Automotive Industry is one of the best in the industry especially for making car parts like Interior, Exterior, Lighting, Climate Control Switches and many more. We have customized our machines for Automotive plastic and polymer components. Special designed screw & barrel, which makes perfect plasticizing effect and faster charging is capable for large shot weight. Upgraded hydraulic system ensures high injection speed and lowers production cycle. This machine can use many different material to produce automotive parts.

Advantages

Energy saving, environmental, Easy plastics processing operations. , quick response, Improve Production efficiency, Specially Designed Screw

Technical Parameters

| MODEL | SHE230 | ||

| INJECTION UNIT | UNIT | A | B |

| Screw diameter | mm | 50 | 52 |

| Shot size(theoretical) | Cm³ | 608 | 658 |

| Shot weight | g | 546 | 592 |

| Injection pressure | Mpa | 184 | 170 |

| Injection rate | g/s | 160 | 176 |

| Screw L/D ratio | L/D | 22.8 | 21.9 |

| Screw speed | r.p.m | 0-180 | |

| Nozzle Diameter | Srmm | 12 | |

| CLAMPING UNIT | |||

| Clamp tonnage | KN | 2300 | |

| Toggle stroke | mm | 510 | |

| Mould Thickness | mm | 200-530 | |

| Space between tie-bars | mm | 535X533 | |

| Ejector stroke | mm | 155 | |

| Ejector tonnage | KN | 70 | |

| Ejector number | Piece | 9 | |

| Hole Diameter | mm | 160 | |

| OTHERS | |||

| Heat power | KW | 16.5 | |

| Max. pump pressure | MPa | 16 | |

| Pump motor power (servo) | KW | 30 | |

| Pump motor power (fixed pump) | KW | 18.5 | |

| Machine dimension | m | 5.8X1.5X1.86 | |

| Machine weight | t | 6.9 | |

| Oil tank capacity | L | 300 | |

Advantages & Features

|