- Home

- >

- Products

- >

- Special Injection Moulding Machine

- >

- PET Preform Injection Molding Machine

- >

- SHE185 PET Preform Injection Molding Machine

SHE185 PET Preform Injection Molding Machine

Series :PET Products Injection Molding Machine

Brand :SANSHUN

Model :SHE185PET

Applications :For making PET Preform

SANSHUN Machinery is one of the top 10 Chinese injection molding machinery manufacturer. We are manufacturing different types of injection molding machines, injection blow molding machine, and Auxiliary equipment. Our machines had been exported to more than 60 countries.

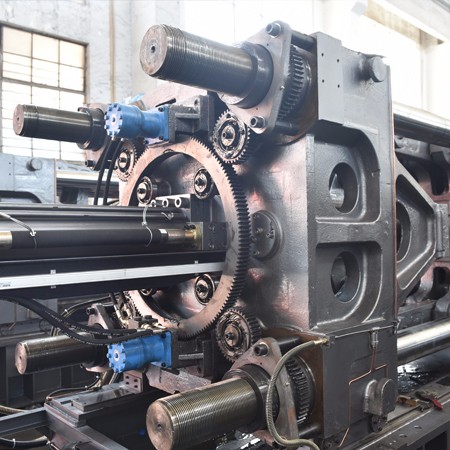

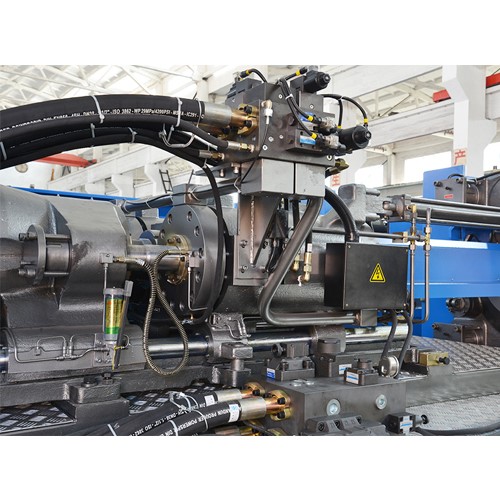

Characteristics

Sanshun Machinery offers Special series of Injection Molding Machines for PET Preform making. PET Special screw highly increases the plasticizing speed and shot weight, lowers the plasticizing temperature and AA value, also achieves better products. Pressure Synchronization System with pressure holding and charge at same time gives the productivity improvement 15%-25%. The Preform which produced by our PET Preform Injection molding machine can stand temperature over 100 degree. With high strength, good transparency and low production costs. Beside an obvious energy saving due to a lower PET melting temperature, preforms by compression require less heating in the blowing phase because the crystals of material are differently oriented.

Advantages

Heat Transfer systems, environmental, low noise, quick response, high-efficiency, high-speed automation, stable weight consistency, low power consumption, full automation of the process

Technical Parameters

| MODEL | SHE185PET | ||

| INJECTION UNIT | UNIT | A | B |

| Screw diameter | mm | 50 | 54 |

| Shot size(theoretical) | Cm³ | 570 | 660 |

| Shot weight | g | 630 | 730 |

| Injection pressure | Mpa | 152 | 130 |

| Injection rate | g/s | 160 | 180 |

| Screw L/D ratio | L/D | 24.5 | 23 |

| Screw speed | r.p.m | 0-140 | |

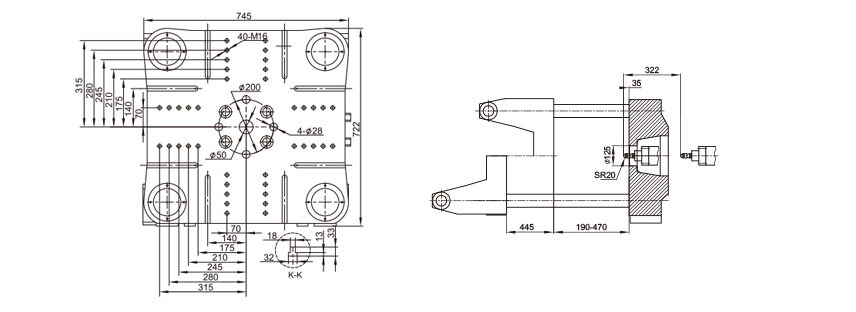

| Nozzle Diameter | Srmm | 20 | |

| CLAMPING UNIT | |||

| Clamp tonnage | KN | 1850 | |

| Toggle stroke | mm | 445 | |

| Mould Thickness | mm | 190-470 | |

| Space between tie-bars | mm | 490X464 | |

| Ejector stroke | mm | 155 | |

| Ejector tonnage | KN | 70 | |

| Ejector number | Piece | 5 | |

| Hole Diameter | mm | 125 | |

| OTHERS | |||

| Heat power | KW | 15.5 | |

| Max. pump pressure | MPa | 16 | |

| Pump motor power | KW | 18.5 | |

| Machine dimension | m | 5.4X1.6X1.75 | |

| Machine weight | t | 6.2 | |

| Oil tank capacity | L | 270 | |

Platen Dimensions

Advantages & Features

|