- Home

- >

- News & Resources

- >

- Our Blog

- >

- How to control the color difference of injection products?

There are many factors affecting chromatic aberration, involving raw material resin, color masterbatch, color masterbatch and raw material mixing, injection molding process, injection molding machine, mold, etc. Because of the wide range of exposure, color difference control technology is also recognized as one of the hard-to-master technologies in injection molding. In the actual production process, we generally control the color difference from the following six aspects.

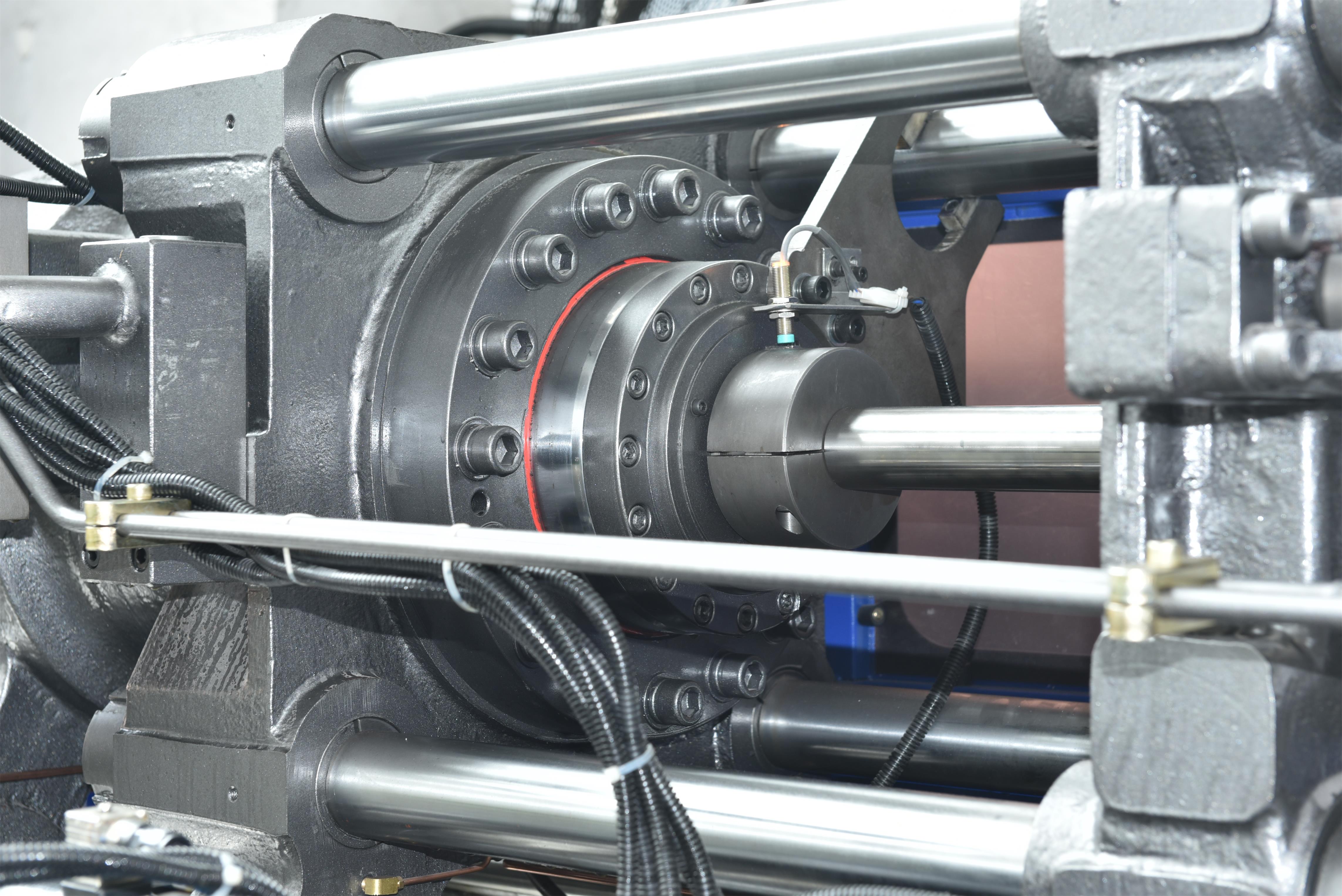

1. Eliminate the influence of injection molding machine and mold factors

To select an injection molding machine with the same capacity as the injection molding main product, if the injection molding machine has problems such as dead spots of materials, it is best to replace the equipment. For the mold casting system, the venting groove and the like cause chromatic aberration, which can be solved by the maintenance mold of the corresponding part of the mold. The injection molding machine and mold problems must be solved before the production can be organized to reduce the complexity of the problem.

2. Eliminate the influence of raw resin and color masterbatch

Controlling raw materials is the key to completely solving chromatic aberrations. Therefore, especially in the production of light-colored articles, the significant influence of the difference in thermal stability of the raw material resin on the color fluctuation of the product cannot be ignored. Since most injection molding manufacturers do not produce plastic masterbatch or color masterbatch themselves, the focus of attention can be placed on production management and raw material inspection to enhance the inspection of raw materials.

In the production, the same product should be made by the same manufacturer, the same brand masterbatch and color masterbatch; for the masterbatch, we should carry out the sampling test before mass production, which must be compared with the last proofreading, and also in this time, if the color The difference is not large, can be considered qualified, as the batch color master has a slight color difference, the color master can be remixed before use, to reduce the color difference caused by the uneven mixing of the color master itself. At the same time, we also need to focus on the thermal stability of the raw material resin and color masterbatch. For the poor thermal stability, we recommend that the manufacturer exchange.

3. Eliminate the influence of uneven mixing of masterbatch and masterbatch

Poor mixing of the plastic masterbatch with the color masterbatch will also make the color of the product change. After the masterbatch and the color masterbatch are mechanically mixed, when the hopper is fed into the hopper through the lower suction, the color masterbatch is separated from the masterbatch due to the action of static electricity, and is easily adsorbed on the hopper wall, which is bound to cause a change in the amount of the masterbatch during the injection molding cycle, thereby generating Color difference.

In this case, the raw material can be sucked into the hopper and then manually stirred. Many companies now use feeders to add color masterbatches, which saves a lot of manpower and provides great help for color difference control. However, many companies are often unsatisfactory due to improper use.

The weight of the feeder added to the masterbatch at a fixed speed depends on the plasticizing time, and the plasticizing time itself is fluctuating, sometimes even fluctuating, so to ensure a constant feeding amount, the feeding time of the feeder must be fixed. And the set time is less than the minimum plasticizing time. When using the feeder, it should be noted that because the feeder outlet is small, after using for a period of time, the raw material powder accumulated in the screw of the feeder may be inaccurate, or even the feeder may stop. It needs to be cleaned regularly.

4. Reduce the effect of barrel temperature on chromatic aberration

In production, it is often encountered that a certain heating coil is damaged or the heating control part is out of control and the burning temperature causes a drastic change in the temperature of the barrel to cause chromatic aberration. The color difference caused by such reasons is easy to judge. Generally, the heating ring damages and the chromatic aberration is accompanied by uneven plasticization, and the heating control part is out of control and often burns with product spot, severe discoloration and even coking. Therefore, the heating part should be inspected frequently during production, and it is found that the heating part is damaged or out of control and replaced in time to reduce the occurrence of such chromatic aberration.

5. Reduce the impact of the injection molding process adjustment

When the non-color difference reason needs to adjust the injection molding process parameters, the injection temperature, back pressure, injection cycle and color masterbatch addition amount should not be changed as much as possible. At the same time, it is necessary to observe the influence of the process parameter change on the color. If the color difference is found, it should be adjusted as much as possible. Avoid the use of high injection speed, high back pressure and other injection molding processes that cause strong shear, to prevent chromatic aberration caused by local overheating or thermal decomposition. Strictly control the temperature of each heating section of the barrel, especially the nozzle and the heating part next to the nozzle.