- Home

- >

- Products

- >

- Special Injection Moulding Machine

- >

- Horizontal Injection Molding Machine

- >

- SHE800 Horizontal Injection Molding Machine

SHE800 Horizontal Injection Molding Machine

Series :Horizontal Injection Molding Machine

Brand :SANSHUN

Model :SHE800

Applications :For different kind of plastic product manufacturing

SANSHUN Machinery is one of the top 10 Chinese injection molding machinery manufacturer. We are manufacturing different types of injection molding machines, injection blow molding machine, and Auxiliary equipment. Our machines had been exported to more than 60 countries.

Characteristics

Sanshun Machinery With vast industry experience and knowledge, we have evolved as the leading manufacturer, exporter and supplier of a broad collection of Horizontal Plastic Injection Moulding Machine to our clients. Our offered products are manufactured using optimum grade raw material and advanced technology in adherence to the universally accepted standards. Owing to their attributes such as rugged construction and sturdiness, these machines are appreciated by our clients. Further, these are checked against various quality parameters and are made available market leading price.

Advantages

Environmental, Shorter Cycle Time, , Improve Production efficiency. low noise, high-efficiency, quick response

Technical Parameters

| MODEL | SHE800 | ||

| INJECTION UNIT | UNIT | A | B |

| Screw diameter | mm | 105 | 108 |

| Shot size(theoretical) | Cm³ | 4670 | 4840 |

| Shot weight | g | 4200 | 4350 |

| Injection pressure | Mpa | 149 | 141 |

| Injection rate | g/s | 780 | 830 |

| Screw L/D ratio | L/D | 21 | 20.4 |

| Screw speed | r.p.m | 0-100 | |

| Nozzle Diameter | Srmm | 18 | |

| CLAMPING UNIT | |||

| Clamp tonnage | KN | 8000 | |

| Toggle stroke | mm | 980 | |

| Mould Thickness | mm | 400-980 | |

| Space between tie-bars | mm | 1016X980 | |

| Ejector stroke | mm | 260 | |

| Ejector tonnage | KN | 186 | |

| Ejector number | Piece | 21 | |

| Hole Diameter | mm | 250 | |

| OTHERS | |||

| Heat power | KW | 51.5 | |

| Max. pump pressure | MPa | 16 | |

| Pump motor power(servo) | KW | 51+51 | |

| Pump motor power (fixed pump) | KW | 37+37 | |

| Machine dimension | m | 11X2.4X2.65 | |

| Machine weight | t | 42 | |

| Oil tank capacity | L | 1300 | |

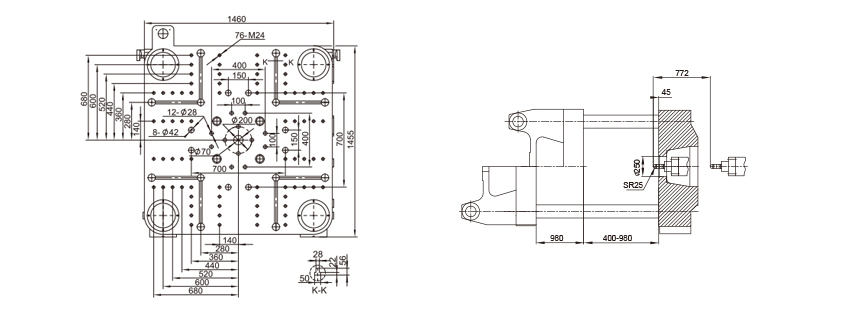

Platen Dimensions

Advantages & Features

|