- Home

- >

- Products

- >

- Special Injection Moulding Machine

- >

- PVC Pipe Making Injection Molding Machine

- >

- SHE168 PVC Pipe Making Injection Molding Machine

SHE168 PVC Pipe Making Injection Molding Machine

Series :PVC Fitting Injection Molding Machine

Brand :SANSHUN

Model :SHE168-PVC

Applications :For making PVC Pipe Fitting

SANSHUN Machinery is one of the top 10 Chinese injection molding machinery manufacturer. We are manufacturing different types of injection molding machines, injection blow molding machine, and Auxiliary equipment. Our machines had been exported to more than 60 countries.

Characteristics

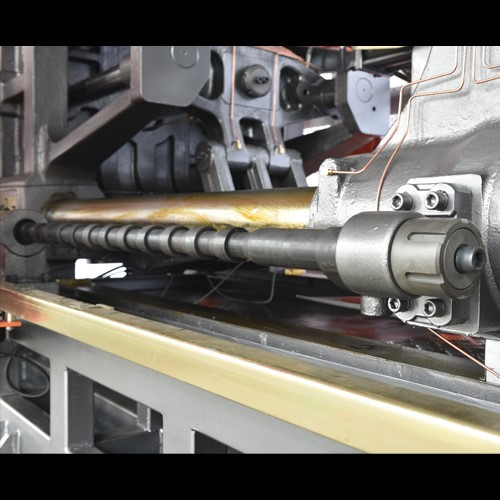

Sanshun Machinery offers Special series of Injection Molding Machines for PVC Pipe Fittings making. Polyvinyl chloride (PVC) is a versatile thermoplastic material that is used in the production of hundreds of products.Specially designed for PVC,UPVC,CPVC,PVC Powder, Bi-alloy Screw & Barrel. Stabilized temperature increasing rate from charging. Highly efficient plasticizing rate and stable injection molding. Product quality is excellent. Specially designed for hard PVC mold, widened the plate metal, convenient to mold installation. Reduce customer cost, increasing the safety of the operator. Standard with fan and wind cover, make sure small material temperature deviation.

Advantages

Heat Transfer systems, Rear & Front Gate Extension, Blowers on Barrel Zones, Specially Designed Screw for PVC Processing, Nitride Screw & Barrel, Seal at Screw End, Extra Heating Zones, stable weight consistency

Technical Parameters

| MODEL | SHE168-PVC | ||

| INJECTION UNIT | UNIT | A | B |

| Screw diameter | mm | 45 | 48 |

| Shot size(theoretical) | Cm³ | 370 | 420 |

| Shot weight | g | 440 | 500 |

| Injection pressure | Mpa | 168 | 148 |

| Injection rate | g/s | 142 | 160 |

| Screw L/D ratio | L/D | 23.1 | 21.7 |

| Screw speed | r.p.m | 0-180 | |

| Nozzle Diameter | Srmm | 12 | |

| CLAMPING UNIT | |||

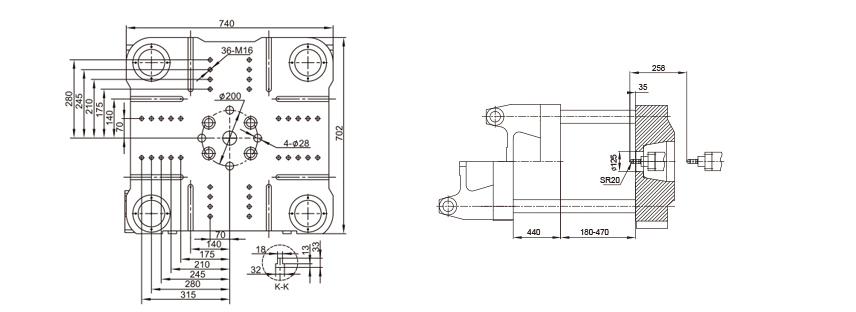

| Clamp tonnage | KN | 1680 | |

| Toggle stroke | mm | 440 | |

| Mould Thickness | mm | 180-4701 | |

| Space between tie-bars | mm | 480X460 | |

| Ejector stroke | mm | 155 | |

| Ejector tonnage | KN | 70 | |

| Ejector number | Piece | 5 | |

| Hole Diameter | mm | 125 | |

| OTHERS | |||

| Heat power | KW | 14.1 | |

| Max. pump pressure | MPa | 16 | |

| Pump motor power | KW | 30 | |

| Machine dimension | m | 5.3X1.4X1.75 | |

| Machine weight | t | 5.5 | |

| Oil tank capacity | L | 250 | |

Platen Dimensions

Advantages & Features

|